Silica Sand Processing Plant

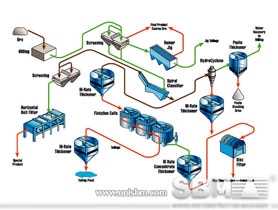

The processing techniques used in mining silica sand are very important. The techniques consist of both wet and dry processes, and at times, process combinations to produce an acceptable product. In the common silica sand making process, jaw crusher is used as primary crushing machine and then goes through the secondary crushing plant.

The sand particles that meet the requirements enter into the sand making machine for making fine sand, while the others enter into the tertiary crushing plant for fine crushing, then go for sand making. The fine sand must be washed by sand washer, washing is the simplest and lowest cost method of cleaning silica sand.

In some of the very pure deposits that are void of heavy minerals, clay and silt, and no surface staining, washing is sufficient to produce acceptable grade product. Then dry the product by drying machine. Sometimes, we need silica powder, so we should grind silica sand with our grinding machine. The ball mill or Raymond mill can grind silica sand into powder very well.

The SBM silica sand processing plant including silica sand crusher, silica sand screen, silica sand washing machines, and grinding machine are used in mining process and silica sand making process. SBM can design silica sand processing flow sheet with crushing screening plant, washing plant and grinding process for quarry in India, USA.

For product information and pricing, Chat with sales agent:

or email us:

[email protected]

Click links below to see related products.