Iron Ore Processing Plant

The following describes about the iron ore mining and processing plant by SBM.

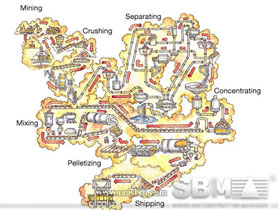

Creating steel from low-grade iron ore requires a long process of mining, crushing, separating, concentrating, mixing, pelletizing, and shipping. The process of mining low-grade iron ore, or taconite, requires massive resources. Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required. The equipment used includes diamond-bit rotary drills, hydraulic shovels and loaders, water wagons, production trucks and heavy-duty conveyors.

Iron ore processing steps: Mining Iron Ore ( mining iron ore begins at ground level ), Crushing the Ore (The crude taconite is delivered to large gyrator crushers, where chunks as large as five feet are reduced to six inches or less), Concentrating Concentrating, Mixing with the Binding Agents, Pelletizing, Pellet Loadout and Shipping.

SBM has built the iron ore processing plant in Ethiopia, China, and India. SBM can offer types of iron ore processing equipment: crusher for crushing plant and mining process, grinding mill for concentration, refining plant.

For product information and pricing, Chat with sales agent:

or email us:

[email protected]

Click links below to see related products.